Table of Contents

- Introduction

- The Purpose and Nature of DDC

- The Anodizing Process and Color Variation

- DDC DSLR Shots: Captured Under Fluorescent Lighting, No Flash

- DDC DSLR Shots: Captured Under Fluorescent Lighting with Flash

- DDC iPhone Shots: Captured Under Fluorescent Lighting, No Flash

- Lighting Variations: Captured In Different Conditions

- Why Manufacturing Marks Exist

- Embracing Geissele’s Standards

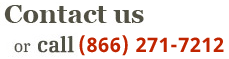

Introduction

Geissele Automatics is known for its high-performance rifles, rails, and accessories, which are trusted by military, law enforcement, and civilian shooters alike. One of the defining characteristics of Geissele products is their distinct finishes, particularly the Desert Dirt Color (DDC). While some customers may have concerns about variations in color and manufacturing marks, it is important to understand that these features are not flaws but rather intentional and unavoidable aspects of Geissele’s meticulous finishing process.

The Purpose and Nature of DDC

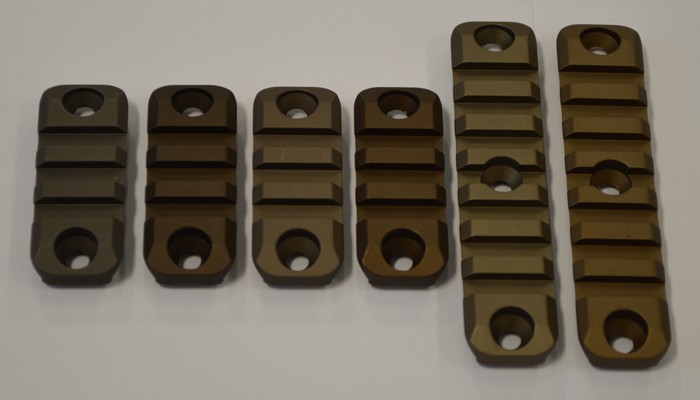

The Desert Dirt Color (DDC) is not a single, uniform shade but rather a range of hues designed to help break up the outline of a firearm in desert environments. Military small arms benefit from this natural camouflage effect, ensuring that no two rifles or accessories are exactly alike. As a result, parts such as handguards, receivers, and rails may have slightly different shades, even when they come from the same production batch. This variation is inherent to the anodizing process and adds to the unique character of each Geissele weapon.

The Anodizing Process and Color Variation

Geissele’s aluminum components undergo a Type 3 Hardcoat anodizing process, which enhances durability, abrasion resistance, and chemical protection. During this process, a layer of aluminum oxide is grown on the surface through an electrochemical reaction. This layer is then dyed to achieve the signature DDC finish. However, several factors influence the final coloration, including chemical concentration, dye absorption, environmental conditions, and even minor batch-to-batch inconsistencies. Because of this, even black anodized parts can display slight shifts in hue under different lighting conditions.

For customers who require a perfectly uniform color across all components, repainting with an aftermarket finish such as Cerakote or DuraCoat is an option. However, it is important to note that these coatings, while aesthetically uniform, are not as durable as Geissele’s hardcoat anodizing and are more susceptible to wear over time.

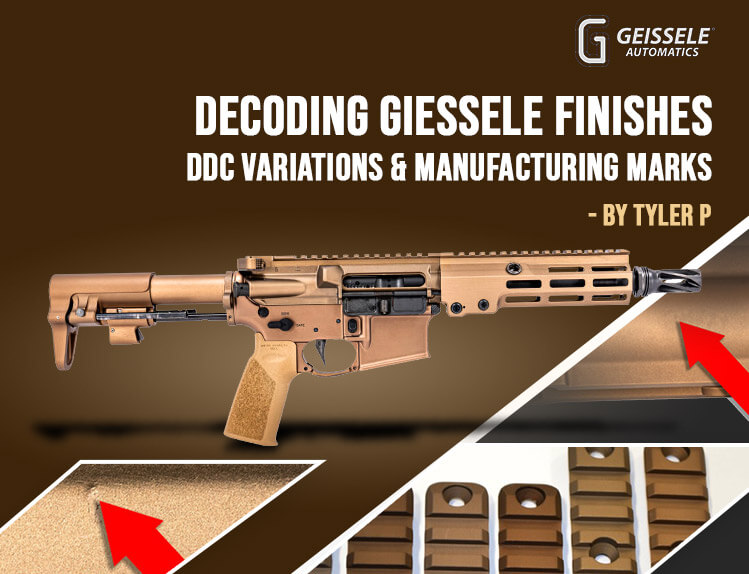

Shop All Geissele Automatics productsDDC DSLR Shots: Captured Under Fluorescent Lighting, No Flash

DDC DSLR Shots: Captured Under Fluorescent Lighting with Flash

DDC iPhone Shots: Captured Under Fluorescent Lighting, No Flash

Lighting Variations: Captured In Different Conditions

*All images sourced from Geissele.com

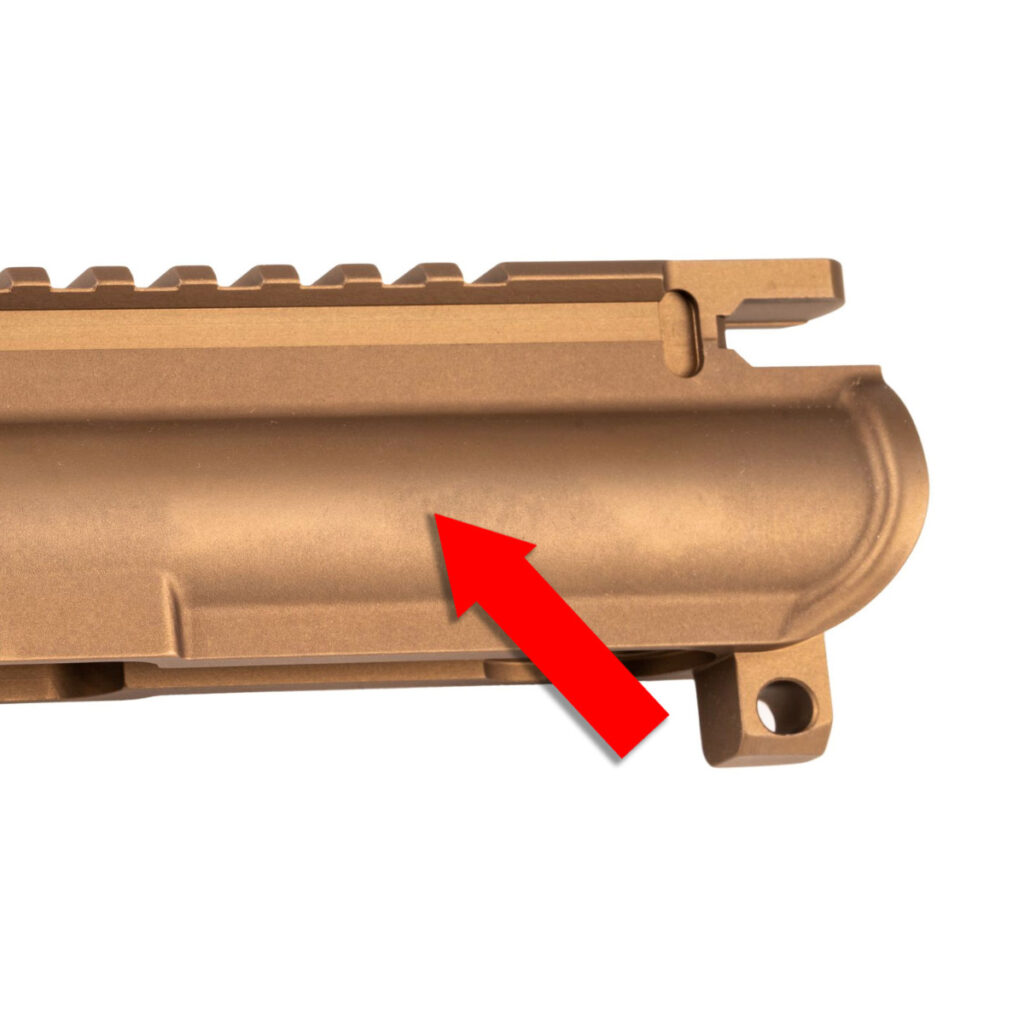

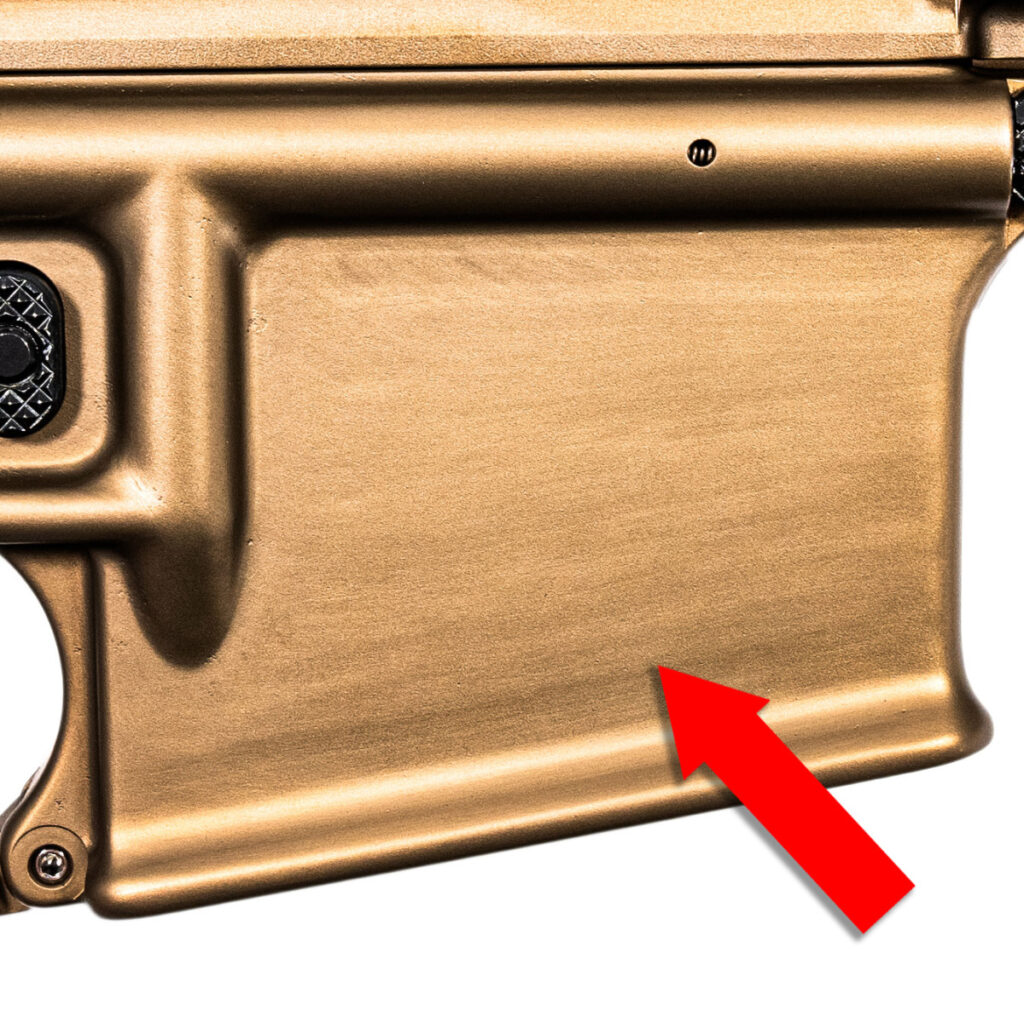

Shop All Geissele Automatics productsWhy Manufacturing Marks Exist

Unlike other manufacturers who use aggressive shot blasting and heavy sandblasting to create a uniform but rough surface, Geissele takes a different approach. Each part undergoes careful hand and machine finishing, preserving the integrity of the material while providing a smooth, velvety texture. This refined process, however, does not erase natural machining marks, small dings, extrusion lines, or alloy segregation shadows—features that are enhanced by the anodizing process rather than hidden. These marks do not compromise performance; rather, they are a testament to the craftsmanship and precision that goes into every Geissele product.

*All images sourced from Geissele.com

Embracing Geissele’s Standards

Geissele’s commitment to superior design means accepting these natural variations as part of the brand’s identity. Customers who prioritize a completely uniform aesthetic may find Geissele’s approach unconventional, but those who understand the reasoning behind these choices recognize the superior function, feel, and durability that come with them. If a flawless, identical finish is a requirement, customers are advised to opt for a painted finish over anodizing.

At the end of the day, a Geissele rifle or accessory is built for performance, reliability, and longevity. The color variations and manufacturing marks make each piece unique and effective in the field. When you choose Geissele, you are choosing battle-tested quality—precision-engineered, hand-finished, and built to exacting standards. Unlike mass-produced products that may prioritize cost-cutting over durability, Geissele parts embody a level of craftsmanship and reliability that stands above the rest.

Shop All Geissele Automatics products